ledKategorie: Liczba wpisów: 1, liczba wizyt: 3353 |

Nadesłane przez: ledlights

dnia 24-09-2023 17:13

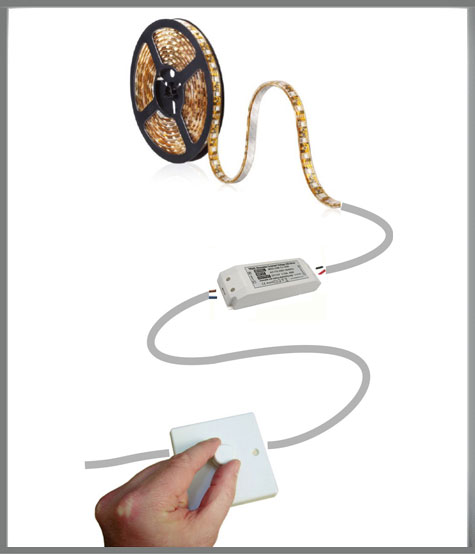

The setup procedures can vary based on the source of your LED strip and the LED power supply. In the subsequent sections, we will delve into the prevalent configurations.

The majority of LED strip light products function on low-voltage DC power. Common DC voltage options include 12V and 24V.

First and foremost, ensure that the power supply's rating aligns with the correct voltage required by the LED strip. Operating the LED strip at a voltage lower than necessary will lead to reduced brightness or even no light output, while supplying an excessive voltage could cause the LEDs to burn out.

Secondly, confirm that the power supply's capacity is suitable for the length of the LED strip you intend to use. You can calculate this by referring to the LED strip's specifications sheet, usually detailing the current or power consumption per unit length.

If both of these electrical criteria are satisfied, we are ready to proceed.

Moving forward, we should examine the compatibility of connectors and plugs between the power supply and LED strip on a physical level.

Given the diverse array of connection types available for Best led light strips and power supplies, the situation might become a tad perplexing. To illuminate this matter (pun intended!), we've thoughtfully constructed the chart provided below.

To begin, identify the connection format utilized on the "Power Supply Side" (highlighted in green). Subsequently, ascertain the connection style employed on the "LED Strip Side" (shaded in blue). Comprehensive instructions for determining these types are outlined below.

Afterward, locate the point where the relevant row and column intersect, corresponding to your specific arrangement. For instance, if your power supply features "Open Wires" and your LED strip employs "DC Receptacles," refer to the lower right square within the chart.

We initiate by examining the type of connector used on the DC output facet of the power supply.

The most prevalent connector type is a DC male plug, similar to the one utilized in Waveform Lighting's FilmGrade power supplies:

- In certain cases, such as with Meanwell power supplies, there might be no plug present—just two wires labeled in red and white:

- Both of these types can be adapted to function with an LED strip. However, the methodology of connection will differ. Thus, it's crucial to ascertain this distinction before proceeding further.

Virtually all LED strips are equipped with copper pads, denoted as (+) and (-), which are visibly marked on the strip itself.

These pads serve as the crucial points for channeling electrical input. Depending on your specific circumstances, you are likely to encounter three distinct scenarios.

In the initial scenario (top row of the chart), if you've segmented an LED strip reel, you'll observe that each segment's end features (approximately) semi-circular copper pads.

When you've procured an entire reel, the manufacturer commonly includes wires already affixed to the led lights ends. These wires can either present as exposed leads (second scenario) or culminate in a DC receptacle (third scenario).

Should you decide to divide the LED strip into shorter sections, you'll inevitably have at least one segment falling into the first scenario.

Consult the chart provided above to discern how to establish connections for each of these scenarios with the power supply.

Remember, a few fundamental principles of electronics apply: the ultimate objective is to link the positive wire (typically red) of the power supply's DC output to the (+) copper pad, and correspondingly, attach the negative or ground wire (usually black or white) of the power supply's DC output to the (-) copper pad.

When you decide to divide the LED strip into shorter segments, it's highly likely that you'll end up with copper pads bereft of any attached wires.

Numerous tutorials and instructional videos often recommend soldering wires onto these copper pads to establish an electrical link. However, soldering might not be suitable for everyone due to its potential messiness and the need for practice to achieve proficiency.

Read more: How to Connect LED Strip Lights Safely and Easily

An alternative approach we propose involves the utilization of solderless connectors. These connectors are purposefully designed to clip onto the ends of the LED strip, ensuring that the wires establish a secure connection with the copper pads. As these clips affix firmly, soldering becomes unnecessary.

In a matter of seconds, you can adeptly convert the copper pads at the extremity of an LED strip segment into functional wires.

Moreover, the beauty of this method lies in its simplicity – by merely releasing the latch, you can effortlessly detach and remove the LED strip from the connector.

When faced with the task of linking multiple LED strip segments to a single power supply, a common question arises: should you connect the first segment to the second one "in series," or should you independently connect two segments to the same power supply?

Typically, opting for a "series" connection might seem simpler, although it could potentially introduce voltage drop concerns. For a comprehensive exploration of the merits and drawbacks of both methods, refer to the detailed analysis available here.

In conclusion, mastering the art of connecting LED strip lights empowers you to craft stunning and customizable lighting setups for various spaces. By ensuring the electrical compatibility of your components, selecting appropriate connectors, and deciding on the optimal configuration, you can seamlessly bring your LED strip lights to life.

Whether you choose to connect them in parallel or series, the key is to follow the guidelines, exercise caution, and make informed decisions to achieve the desired ambiance and functionality. With the knowledge gained from this guide, you're well-equipped to embark on your LED strip lights journey and illuminate your surroundings creatively and effectively.

Read more: How To Set Up LED Strip Lights